產(chǎn)品中心

產(chǎn)品中心

無菌灌裝機(jī)

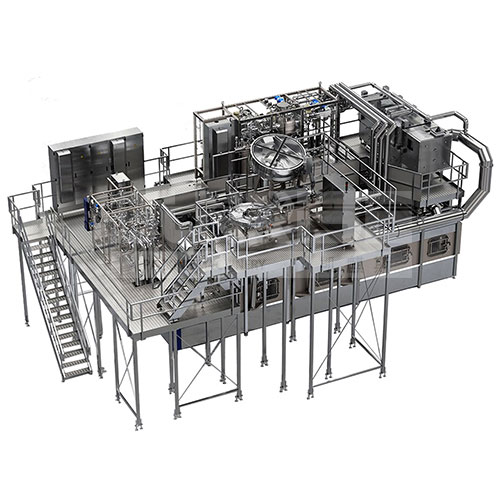

干法無菌冷灌裝系統(tǒng)

產(chǎn)品描述

主要結(jié)構(gòu)特點(diǎn)

●干法無菌適合中性、酸性液態(tài)食品的塑瓶無菌包裝。用于奶,鮮榨果汁,咖啡飲料,含乳飲料、茶飲等高端液態(tài)食品。整機(jī)全自動(dòng)完成進(jìn)瓶、取放瓶、瓶輸送、瓶滅菌烘干、定量灌裝、伺服理蓋、蓋滅菌烘干、加蓋、擰蓋、出瓶、取放瓶和成品輸送。采用***的干法滅菌技術(shù)和直線步進(jìn)式設(shè)備架構(gòu),與傳統(tǒng)的回轉(zhuǎn)式無菌灌裝設(shè)備相比,占地面積及運(yùn)行能耗均有大幅降低,是瓶裝液體無菌包裝的優(yōu)選裝備。

●干法無菌灌裝主要通過控制干燥空氣的流量、濕度和溫度來達(dá)到無菌狀態(tài),所以在使用的過程中需要保持相對(duì)穩(wěn)定的環(huán)境溫度和濕度。

●干法無菌灌裝的主要特點(diǎn)是無需加入水份,即在接觸環(huán)境中維持較低的水份含量,從而防止微生物生長。

Main structural features

●Dry aseptic packaging is suitable for sterile packaging of neutral and acidic liquid foods in plastic bottles. Used for high-end liquid foods such as milk, freshly squeezed fruit juice, coffee drinks, dairy containing drinks, tea drinks, etc. The whole machine is fully automated to complete bottle feeding, bottle picking and placing, bottle conveying, bottle sterilization and drying, quantitative filling, servo cap unscrambling, cap sterilization and drying, cap feeding, cap twisting, bottle dispensing, bottle picking and placing, and finished product conveying. By adopting advanced dry sterilization technology and linear step-by-step equipment architecture, compared with traditional rotary aseptic filling equipment, the footprint and operating energy consumption are significantly reduced, making it the preferred equipment for aseptic packaging of bottled liquids.

●Dry aseptic filling mainly achieves sterile state by controlling the flow rate, humidity, and temperature of dry air, so it is necessary to maintain relatively stable environmental temperature and humidity during use.

●The main feature of dry aseptic filling is that it does not require the addition of water, maintaining a low moisture content in the contact environment to prevent microbial growth.

蘇公網(wǎng)安備32132302010360號(hào)

蘇公網(wǎng)安備32132302010360號(hào) 撥打電話

撥打電話